Automotive Industry Standards of the People's Republic of China

QC/T993-2015

Explosive transport vehicle

Released on April 30th, 2015 Implemented on October 1st, 2015

Issued by the Ministry of Industry and Information Technology of the People's Republic of China

catalogue

Preface II

1 Scope 1

2 Normative references 1

3 Terms and Definitions 2

4 Requirements 3

5 Test Method 5

6 Inspection Rules 6

7 Signs, Identification, and User Manual 7

8 Accompanying documents, transportation, and storage 7

Appendix A (normative appendix) Technical requirements and inspection rules for explosion-proof containers 9

Appendix B (informative appendix) List of Civil Explosive Articles 13

Preface

This standard is drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that certain contents of this standard may involve patents, and the issuing authority of the standard does not assume the responsibility of identifying these patents.

This standard is proposed by the Ministry of Industry and Information Technology of the People's Republic of China.

This standard is under the jurisdiction of the National Automotive Standardization Technical Committee.

Drafting units of this standard: Zhengzhou Hongyu Special Purpose Vehicle Co., Ltd., Weapon Industry Safety Technology Research Institute, China Weapon Industry Second and Third Research Institute, Shanghai Aviation Special Vehicle Co., Ltd., Jinhua Jiangyouming Carriage Manufacturing Co., Ltd., Zhongtian High tech Special Vehicle Co., Ltd., Shandong Zhengtai Hill Special Purpose Vehicle Co., Ltd., Jiangxi Jiangling Automobile Group Modified Vehicle Co., Ltd Hunan Jinhua Vehicle Co., Ltd., Hunan Futeng He Security and Explosion Prevention Technology Co., Ltd., and Hanyang Special Vehicle Research Institute

The main drafters of this standard are Wang Jianguo, Bai Chunguang, Hou Yonghua, Zhe Enyi, Tu Zhongming, Jiang Youming, Duan Liancheng, Dong Jinhui, Ling Liangxing, Dai Yong, Tang Heping, Yao Hongzhi, Xia Jie, Li Genyun, He Xiaosan, and Wang Dongtang

This standard is issued for the first time.

Preface

This standard is drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that certain contents of this standard may involve patents, and the issuing authority of the standard does not assume the responsibility of identifying these patents.

This standard is proposed by the Ministry of Industry and Information Technology of the People's Republic of China.

This standard is under the jurisdiction of the National Automotive Standardization Technical Committee.

Drafting units of this standard: Zhengzhou Hongyu Special Purpose Vehicle Co., Ltd., Weapon Industry Safety Technology Research Institute, China Weapon Industry Second and Third Research Institute, Shanghai Aviation Special Vehicle Co., Ltd., Jinhua Jiangyouming Carriage Manufacturing Co., Ltd., Zhongtian High tech Special Vehicle Co., Ltd., Shandong Zhengtai Hill Special Purpose Vehicle Co., Ltd., Jiangxi Jiangling Automobile Group Modified Vehicle Co., Ltd Hunan Jinhua Vehicle Co., Ltd., Hunan Futeng He Security and Explosion Prevention Technology Co., Ltd., and Hanyang Special Vehicle Research Institute

The main drafters of this standard are Wang Jianguo, Bai Chunguang, Hou Yonghua, Zhe Enyi, Tu Zhongming, Jiang Youming, Duan Liancheng, Dong Jinhui, Ling Liangxing, Dai Yong, Tang Heping, Yao Hongzhi, Xia Jie, Li Genyun, He Xiaosan, and Wang Dongtang

This standard is issued for the first time.

JB/T 5943 General Technical Conditions for Welding Parts of Construction Machinery

JT 230 Automotive Static Conductive Rubber Trailer

JT 230 Automotive Static Conductive Rubber Trailer

3 Terms and definitions

The terms and definitions established in GB/T17350 and the following apply to this document.

3.1

Explosive transport vehicle

Vehicles transporting explosives. Including civilian explosives transport vehicles, fireworks and firecracker transport vehicles, and explosives co carrier vehicles.

3.2

Explosions of civilian explosives

Under external influences (such as heating, impact, etc.), intense chemical reactions can occur, instantly generating a large amount of gas and heat, causing a sharp increase in surrounding pressure, explosion or intense combustion, and causing damage to the surrounding environment. This standard refers to Class 1 of the "GB6944-2012 Classification of Dangerous Goods" and is listed in the "List of Civilian Explosives".

4 Requirements

4.1 Whole vehicle

4.1.1 Vehicles shall be manufactured according to the approved product drawings and technical documents in accordance with the prescribed procedures and comply with the requirements of this standard.

4.1.2 Purchased and outsourced parts should comply with relevant regulations and have a manufacturer's certificate of conformity. They can only be used after passing the inspection by the entire vehicle factory. All self-made parts can only be assembled after passing the inspection.

4.1.3 The vehicle should be able to operate normally under the following conditions:

a) Environmental temperature -40~55 ℃;

b) Driving on highways above Class 4.

4.1.4 The overall dimensions, axle load, and mass limits of the vehicle should comply with the provisions of GB1589.

4.1.5 The driving safety requirements of vehicles should comply with the provisions of GB7258.

4.1.6 The installation requirements for external lighting and light signaling devices of vehicles should comply with the provisions of GB4785.

4.1.7 Vehicles should comply with the relevant provisions of GB21668.

4.1.8 Protective devices should be installed on the side of vehicles with a total mass greater than 3500kg, including the outer side of the fuel tank, and the protective devices should comply with the provisions of GB11567.1; The rear end of the vehicle should be equipped with protective devices that comply with the provisions of GB11567.2.

4.1.9 On the front and rear protective devices of the vehicle, an area of no less than 150mm should be installed × 80mm, with a thickness of no less than 40mm buffer.

4.1.10 Vehicles should be equipped with Class 1 anti lock braking devices that comply with the provisions of GB/T13594.

4.1.11 The vehicle should be equipped with a retarder or other auxiliary braking device, and the front wheels should be equipped with disc brakes.

4.1.12 Vehicles should be equipped with a speed limit system, which should comply with the provisions of GB/T24545. The maximum speed set by the speed limit system should not exceed 80km/h

4.1.13 The front and rear of the vehicle should be equipped with towing hooks or towing devices.

4.1.14 Vehicles with a total mass greater than 3000kg should use compression ignition engines.

4.1.15 The exhaust pipe of the vehicle engine should be placed in front of the front end face of the cargo compartment, and the arrangement of the exhaust pipe should be able to avoid heating and igniting the goods. The clear distance from the fuel tank and oil pipe should not be less than 200mm, and the distance from the exposed electrical switch should not be less than 100mm; When the exhaust pipe of the vehicle engine is installed below the cargo floor, a heat insulation board should be installed between the exhaust pipe and the cargo floor. All exhaust pipes should be equipped with motor vehicle exhaust spark arresters, and their performance should comply with the provisions of GB13365.

4.1.16 Vehicles should be equipped with a smoke and fire alarm system, with smoke and fire detectors located in the cargo compartment and alarm buzzers located in the driver's cab. The smoke and fire detectors should comply with the provisions of GB4715; Vehicles with a total mass of ≥ 2000kg should also be equipped with an anti-theft alarm system on the cargo door. The anti-theft alarm triggering device should be located on the rear and side doors of the cargo door, and the alarm buzzer should be located in the driver's cab. When the rear or side doors are opened, the anti-theft alarm should sound within 10 seconds; Vehicles with a total mass of ≥ 9000kg should also be equipped with a rear video monitoring system. The video camera should be located outside the rear of the cargo compartment, and the monitor should be located inside the driver's cab. The camera's wide angle should be ≥ 140 °. The control device of the alarm system should not be controlled by the chassis power switch, and the alarm sound level should be ≥ 100dB.

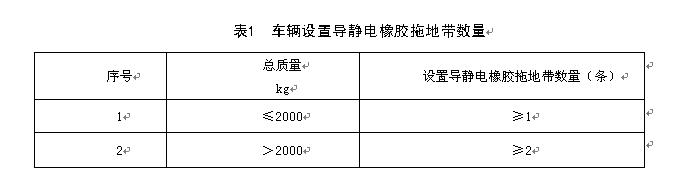

4.1.17 The frame should be equipped with a static conductive rubber towing strap, which should be equipotentially connected to the frame. The technical indicators of the electrostatic conductive rubber towing strip should comply with the provisions of JT230. The number of static conductive rubber towing strips installed on the vehicle is shown in Table 1.

Table 1 Number of Static Conductive Rubber Towing Belts Installed on Vehicles

4.1.18 The chassis frame and cargo compartment should be equipotentially connected.

4.1.19 The vehicle should have good rainproof sealing performance, and there should be no seepage or leakage during the rainproof sealing test.

4.1.20 Vehicles should be equipped with radial tires and the use of retreaded tires is strictly prohibited.

4.1.21 Vehicles should be equipped with a driving recorder that can record, store, display, print or output information on the vehicle's driving speed, time, mileage, and other vehicle status. Its technical requirements should comply with the relevant provisions of GB/T19056.

4.1.22 Two dry powder fire extinguishers suitable for the explosive items loaded should be equipped in prominent positions of the vehicle, and the fire extinguishers should be securely fixed and easy to access.

4.2 Vehicle cargo compartment

4.2.1 The cargo compartment should be a metal skin enclosed structure.

4.2.2 The inner skin material of the cargo compartment should be made of flame-retardant materials that do not cause sparks due to impact. It is recommended to use non-ferrous metal materials or marine plywood, and the inner surface of the marine plywood should be coated with fireproof paint.

4.2.3 The inner and outer skin of the cargo compartment should be flat and free from bumps and scratches. The inner and outer skin should be tightly bonded to the skeleton without any hollowing defects. Riveting and sealing strips should be arranged neatly, and the density of rivets should be appropriate. The outer surface of the cargo compartment sidewall is 1000mm × The flatness tolerance within the 1000mm range should not exceed 2mm.

4.2.4 The gaps between the inner and outer skins of the cargo compartment should be filled with flame-retardant and heat-insulating materials.

4.2.5 There should be no protruding sharp corners or edges inside the cargo compartment, and fastening devices that can fix the goods should be installed inside the cargo compartment.

4.2.6 The front inner wall panel of the cargo compartment should be equipped with rubber products that can alleviate cargo collision.

4.2.7 The floor of the cargo compartment should be laid with flame retardant and static conductive adhesive plates, which should not wrinkle or warp, and the joints should be compacted and reliable. The thickness of the flame retardant and static conductive adhesive board should not be less than 5mm.

4.2.8 The door opening and closing should be flexible, and anti-aging rubber sealing strips should be installed around the door, which should comply with the provisions of QC/T639.

4.2.9 The door should be reliably locked, and the door lock device should have anti-theft and anti prying functions.

4.2.10 The cargo compartment floor should have good electrostatic conductivity, with a system resistance value of 5.0 × 104~1.0 × 108 Ω.

4.3 Civilian explosive transport vehicles

4.3.1 The side walls of the cargo compartment of civilian explosive transport vehicles should be equipped with ventilation windows with rainproof functions, which should be able to prevent foreign objects from entering.

4.3.2 It is strictly prohibited to install any lighting fixtures and other electrical equipment other than smoke and fire detectors in the cargo compartment of civilian explosive transport vehicles.

5 Test methods

5.1.1 The measurement of vehicle external dimensions shall be carried out in accordance with the provisions of GB/T12673, and the measurement of axle load and mass shall be carried out in accordance with the provisions of GB/T12674.

5.1.2 The driving safety related tests of vehicles shall be carried out in accordance with the relevant provisions of GB7258.

5.1.3 The inspection of the external lighting and light signaling devices of the vehicle shall be carried out in accordance with the provisions of GB4785.

5.1.4 The testing of vehicle side and rear lower protection devices shall be carried out in accordance with the provisions of GB 11567.1 and GB 11567.2. Measure the buffer size of the front and rear protective devices.

5.1.5 Visually inspect the installation position of the exhaust pipe and measure the relative position between the exhaust pipe and the fuel tank with a ruler. When the exhaust pipe is installed below the cargo compartment floor, the reliability and effectiveness of installing an insulation board between the exhaust pipe and the cargo compartment floor should be checked.

5.1.6 Check the installation position and quantity of static conductive rubber towing strips.

5.1.7 Check the installation positions of hazard alarm systems, smoke and fire detectors, alarm buzzers, anti-theft alarm systems, and rear video monitoring systems for vehicles transporting civilian explosives, and test their functional effectiveness.

5.1.8 Check the specifications of the tires and the number of dry powder fire extinguishers.

5.1.9 Rainproof sealing test

The carriage door is closed normally. When the rainfall intensity is ≥ 0.12mm/s, a rain gauge should be used to measure the rainfall. The artificial rainfall on the rain test bench should cover the entire carriage. After a 15 minute rain proof sealing performance test, dry the external water accumulation of the carriage, open the car door, and check for water ingress and leakage in all parts of the carriage.

5.1.10 Visually inspect the structure of the cargo compartment, ventilation windows on the side walls of the cargo compartment, rubber products equipped to alleviate cargo collisions, flame retardant and static conductive rubber plates laid, and measure their thickness and dimensions, as well as safety components such as door rubber seals.

5.1.11 Static conductivity test

The interior of the cargo compartment should be clean, and a megohmmeter should be used to measure the resistance between the floor of the cargo compartment and the connection of the towing strip. Measure one point every 2m2 and calculate the average value.

5.1.12 Alarm performance test

Open the rear or side door, check if the alarm device in the driver's cab sounds within 10 seconds, and measure the sound level of the alarm using a noise meter.

6 Inspection Rules

6.1 Factory inspection

6.1.1 Each product should undergo factory inspection, and can only be shipped after passing the inspection by the quality inspection department of the manufacturer and issuing a product certificate.

6.1.2 Factory inspection items:

a) Appearance;

b) Vehicle size and mass parameters;

c) Signs and markings;

d) Installation of external lighting and light signaling devices;

e) Installation dimensions of protective devices;

f) Exhaust pipe installation;

g) Functional inspection of hazard alarm system;

h) Rainproof sealing;

i) Anti theft alarm performance.

6.2 Type inspection

6.2.1 Type inspection should be carried out in one of the following situations:

a) When a new or old product is transferred to another factory for trial production and finalization;

b) Accumulated normal production output of 2000 vehicles;

c) When production resumes after 3 years of product discontinuation;

d) After formal production, if there are significant changes in materials and processes that may affect product performance;

e) When there is a significant difference between the factory inspection and the type inspection.

During the type inspection in 6.2.2, if it falls under the two situations of a) and b) in 6.2.1, the inspection should be carried out in accordance with Chapter 4, QC/T252, and relevant national regulations; If it falls under the condition of c) in 6.2.1, the dedicated performance should be inspected; If it falls under the two situations of d) and e) in 6.2.1, only the affected items can be inspected.

7 Signs, Identification, and User Manual

7.1 Marks and Identification

7.1.1 There should be safety sign graphics and text on the vehicle. Safety signs, signs, and lights should comply with the relevant provisions of GB13392, GB20300, and GB7258.

7.1.2 Product labels should be installed on the vehicle, and the content of the labels should comply with the provisions of GB/T18411 and GB7258.

7.1.3 The side and rear of the vehicle compartment should be equipped with reflective markings and orange reflective tape that can reflect the outline of the cargo compartment, and their requirements should comply with the provisions of GB20300 and GB7258. Vehicles with a total mass greater than or equal to 12000 kg should also be equipped with rear end marker plates that comply with GB25990 regulations.

7.1.4 The inner side of the vehicle's cargo compartment door should be pasted with the "Transportation Table for Civilian Explosives in the Same Vehicle" that meets the storage requirements of hazardous materials in the same warehouse as specified in the GB50089 standard.